OEE–Overall Equipment Effectiveness–three little letters packing a big punch in manufacturing! Ever chatted with an engineer about numbers and seen their eyes light up when discussing how efficient their machines are? Yep, that’s OEE for you. Think of OEE as the health check-up for your machines. It doesn’t just take your equipment’s pulse; it tells you if it’s firing on all cylinders or just sputtering along.

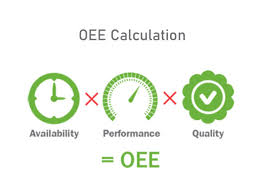

So, why does everyone keep banging on about OEE like it’s the holy grail? Because, in essence, it lays bare the performance of manufacturing equipment. OEE spots how much your machines are utilized, produces high-quality outcomes, and performs efficiently. These three aspects–or let’s call them the Three Amigos of OEE: Availability, Performance, and Quality.

You know that feeling when you’ve planned a perfect barbecue but then it starts raining cats and dogs? That’s a bit like equipment downtime. Imagine if your machinery unexpectedly goes out like a light. OEE helps you pinpoint these hiccups. Availability is all about how much time the machine is up and running versus the time it’s down. And yes, that includes unplanned breakdowns, scheduled maintenance, or just the usual switch-on-switch-off routine.

Now, let’s talk about speed. Ever tried running a marathon without having trained for it? You’ll most probably lag behind. Similarly, Performance measures how fast the equipment runs versus its maximum potential speed. If your machines are slogging away slowly rather than zipping through tasks, you’re losing valuable time.

Finally, you reach the golden child: Quality. Think of it as the judgmental food critic at your barbecue. Quality isn’t shy about pointing out those overcooked burgers (defects). OEE’s Quality metric keeps a hawk’s eye on the number of defective parts that roll out of your equipment.

Let’s get our hands dirty with some numbers. Imagine you have a machine that’s capable of running 10 hours a day. During a week, it stalled for 2 hours, ran slower than expected for another 1.5 hours, and ended up with 3% defective products. With simple multiplication and fractions, you can calculate OEE. And boy, nothing pumps up the adrenaline like a math exercise!

But hold on, keep your eyes peeled. Even with stellar numbers, complacency is a no-go zone. Everyone wants to keep chugging higher, right? How do you inch towards that six-sigma nirvana? Continuous improvement is not a snazzy buzzword but a lifeline.

Picture this: You’re whipping up a storm in the kitchen and suddenly realize you’ve added too much salt. Do you just chuck the dish away? No, you adapt, tweak, and improve. OEE data offers that crucial feedback loop. Just like you’d adjust your recipe next time, you’ll learn where to grease the wheels.

Now, what’s the value of all this mumbo-jumbo? Think bottom line. If your machines work like Swiss watches, churning out high-quality products at breakneck speed, you’re on your way to a fatter wallet. OEE doesn’t just sound cool to throw around in meetings; it’s a game-changer for profits.

Ready for a spicy tidbit? Many companies see a significant uptick in their efficiency just by implementing basic OEE measures. It’s like finding a $20 bill in your old jeans. Pleasant surprise, right? And it doesn’t have to be an all-or-nothing venture. Small tweaks can lead to big payoffs.

Roll up those sleeves and get that data flowing. Don’t just view OEE as another metric; it’s the Sherlock Holmes for your manufacturing floor. It helps you dig out inefficiencies hiding in plain sight. Make those minor adjustments and watch the magic unfold.

In our tech-fueled world, data is the new oil, and OEE is your drilling rig. Embrace it, exploit it, and transform those numbers into actionable insights. Let’s toast to a more profitable, efficient, and high-quality future. Welcome to the wonderful, numbers-laden, and incredibly fulfilling journey that is OEE!